Quote:

Originally Posted by Graham Short

Guys, it's only the last few years I've realised that this miniature work is being regarded as an art form. The magnification has been 'magnified' by the press along the way! I think the confusion was caused because when journalists came to see the microscope I use. They could see it has a maximum 400x magnification. I work under a microscope, not a glass, much less than 400x, and when the finished job is viewed it is set in a domed case under a 30x or 40x microscope.

I've been working on steel pins for years, but again, it's only recently I've started using gold pins. Much easier to work on. Last year I finished a portrait of our queen on a grain of rice. not so much a caricature, but a real drawing of her, showing her hair and the jewels in her crown. For some reason, this didn't get the publicity I'd hoped for. I now have an agent managing my affairs and everything is going well.

|

Quote:

Originally Posted by Graham Short

(Steve, the engraving is along the sharp edge. You are right, the blade had to be prepared to get a flat edge).

|

Graham, Again ,the micro engraving intrigues me but you are seem to say what letter height to shoot for or what letter height you are doing. This

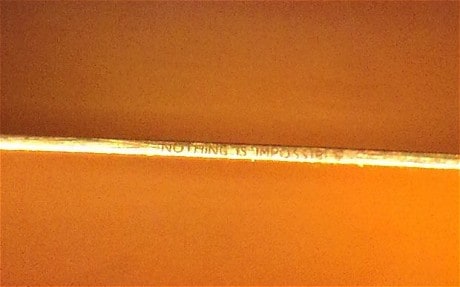

write-up mentions "a tenth of a millimetre" (.1 mm). I googled and found.

Here it is. It mentions 20 microns.

Edit: Hey.. another thought to figure out scale since he isn't saying. Graham mentioned a 30 to 40x scope. With this we may be able to have a closer idea of text size by zooming our scopes to that power and matching the size in the press photo to use as scale. Maybe just zooming in to that power on a fine graduated ruler could work and measuring the field of view at that scale. That would give the approx distance from one edge of the photo to the other.

Figuring it that way the letter height comes out around the .005". This means the edge of the blade we are looking in the photo must be the full width of a razor blade without the edge which correlates to Graham's reply when asked how much of the cutting edge is ground or stoned away to make a flat area to provide a place to put the letters on:

Quote:

Originally Posted by Graham Short

(Steve, the flat I put on the blade is as large as I can get away with!) I couldn't do it without.

|

Okay, maybe makes sense and the above photo of Graham's is of the full thickness of the blade after the cutting edge is sanded away. I can see slight rounding of the surface along with a few sanding or stoning scratches left.

I didn't anneal the one I did in the timed 12 minutes, but if others try it you could first heat the razor blade to a dull red and let air cool. A torch or just a candle should work since the metal is so thin. This will make the metal softer and easier to engrave. Now stone or sand away the cutting edge and engrave. Or engrave the side edge of the blade.

___________